How many do you know O Duster?

24-07-08

Summary:

Correct operation and maintenance are the key to ensuring their long-term stable operation and dust removal effect.

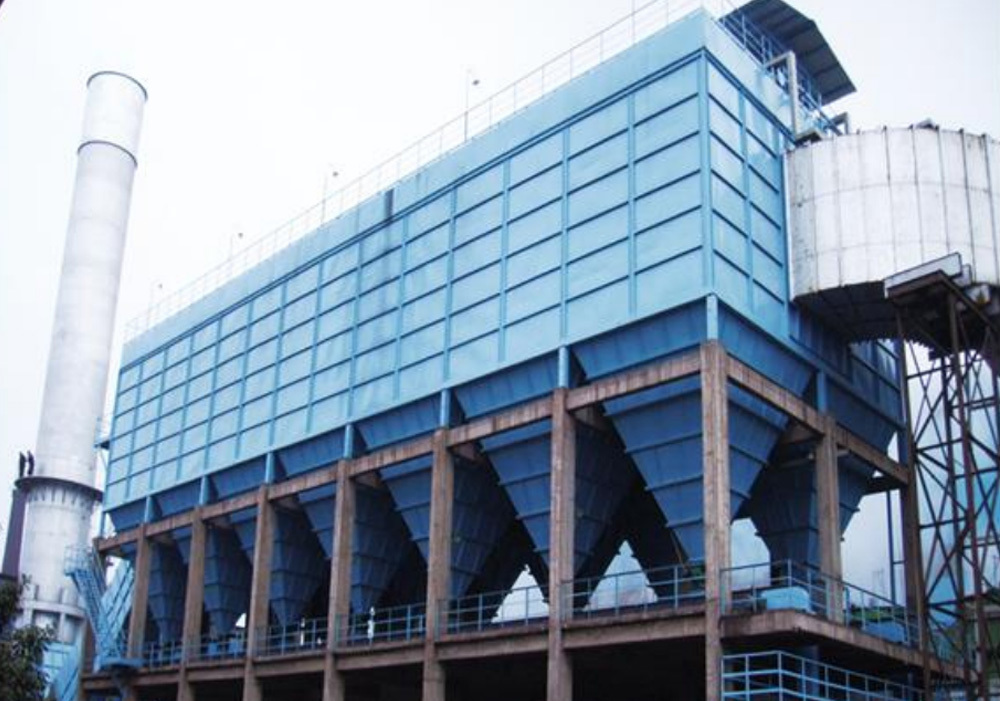

The cloth bag dust collector is an efficient industrial dust removal equipment whose main role is to capture the fine dust particles in the gas through the filter material (filter cloth), thereby purifying the exhaust and protecting the environment. This equipment is widely used in various industrial production processes, such as metallurgy, chemical industry, building materials, tobacco and other industries.

Working principle:

1. Vacuum gas inlet: Vacuum gas enters the ash part of the dust bag with the cloth bag through the fan, where the coarse partial dust will enter the ash bucket due to collision and speed reduction.

2. Filtration process: fine dust particles enter the gas bag chamber and remain in the filter bag due to the inertia, diffusion, barrier and static electricity of the filter material.

3. Purified gas release: The filtered clean gas is released from the bag and discharged through the exhaust pipe.

4. Ash cleaning system: The ash accumulation on cloth bags can be removed by gas washing method or pulsed air flow spray method.

Selection principle:

1. Emission standard: The selected dust collector must meet national and local emission standards to ensure that the emission concentration is within the specified limit.

2. No secondary pollution: new pollutants should not be generated during the dust removal process, and the dust to be captured should be properly treated.

3. Economics: Subject to environmental protection requirements, consider one-time investment, operating and operating costs and equipment energy efficiency factor.

Influential factors:

-The nature of the gas and the characteristics of solid particles: including temperature, humidity, viscosity and other properties of the gas, as well as the size, density and shape of the solid particles.

-Flow and differential pressure treatment: Determine the gas flow rate for treatment and the desired pressure drop range, select the appropriate size and number of bags.

-Processing efficiency requirements: select the type of filter material and fabric bags according to the desired processing efficiency of solid particles.

-Application conditions and standards: consider working environment conditions such as temperature change, chemical corrosion, etc. D., To ensure compliance with relevant standards and requirements.

Use and maintenance:

-Installation: When installing, make sure that the fans and motors are strong, as well as the seal of the inlet and export pipelines.

-Use: Turn on the fan to filter the air containing the dust through the filter bag, and pay attention to adjust the air volume and ash removal frequency.

-Maintenance: regularly check the wear of the filter bag, replace the damaged filter bags in a timely manner, clean the internal dust, check the working condition of the equipment, perform lubrication and maintenance.

Dust bag type:

-- Pulse dust collector from cloth bags: Pulse spray removal of ash.

-Electrostatic dust collector: dust adsorption through static electricity.

-Cyclone dust collector: separates dust by centrifugal force.

-Wet dust collector: catch dust through water droplets or water film.

Thus, with carefully designed operating mechanisms and principles of choice, a dust collector with cloth bags can also reflect economic and practical value while ensuring compliance with environmental protection standards. Correct operation and maintenance are the key to ensuring their long-term stable operation and dust removal effect.

Dust collector

Previous page:

Next page: